Paper in PDF

In the context of informationization and intelligent industry, many logistics companies continue to seek warehouse transformation solutions, and move towards building a comprehensive logistics enterprise based on information management, multi-function, multi-network, people-oriented and linkage interaction.

One of our client, according to their business features, puts into operation a smart warehouse managed by industrial smart camera and robot products: with intelligent storage robots, OCR character recognition, video monitoring and other systems to achieve automatic sorting, automatic weighing, automatic measurement and autonomous robot handling, autonomous robot loading into the warehouse and visual management throughout the process have greatly improved warehouse operation efficiency and accuracy. They upgrade the traditional warehouse to multifunctional, integrated and intelligent warehouse services Change.

Information management

After the smart warehouse management system is adopted, various resources can be integrated, centrally managed, and comprehensively applied. It is not only the electronic and informatization of warehouse business work, but also the establishment of an intelligent warehouse management platform model based on social logistics services.

Refined management

The intelligent storage management system supports in-and-out-of storage management and location management. The flexible and diversified management mode and refined management technology make the operation efficiency and accuracy of intelligent storage reach a new height.

Saving cost

Manpower

The minimum configuration of the number of warehouse operators is reduced to 4 people / warehouse: 1 person unloading, 1 person putaway, 1 person loading the car, and 1 person dispatching. The industrial smart camera reads and weighs to reduce the labor cost of the object data collection

Operating efficiency cost

The maximum speed of the sorting line in the warehouse can reach 5 seconds / piece, the efficiency of the workbench into the warehouse is 900 pieces / hour, and the efficiency of the outbound packing is increased by 35%

Management cost

Realize remote management and remote control of field operations through video surveillance equipment; real-time analysis of platform data reports and results required by management; diversification of warehouse inventory to meet the real-time monitoring and verification of inventory data by the business layer

Reconstruction of all aspects of warehouse logistics, such as pushing delivery order information in the order cart, intelligent sorting platform, industrial smart camera code reading and weighing platform, accurate scanning of workbench storage, and intelligent scheduling system The technologies such as optimal shelf layout, intelligent out-of-box and in-box, out-of-warehouse yard picking technology application, and out-of-house scanning accurate verification are all advanced intelligent applications in the industry. Based on this, we have achieved third-party logistics-based Intelligent warehouse logistics model for the industry.

In summary, the smart warehouse project is easy to implement, which frees up manpower in some operating positions and greatly improves work efficiency and accuracy. It’s the feedback from our customer.

Relevant technologies

The deep learning deployment of the Intel OpenVINO tool suite optimizes the trained model, performs inference analysis, and provides an API for applications to send data to the inference engine. With the optimization of the OpenVINO, the inference performance will be significantly improved, and the benchmark results will be significantly improved.

ü Run multiple instances of the OpenVINO, each of which is tied to one or more cores, which helps improve core utilization.

ü Reduce time to market with libraries and pre-optimized kernels.

ü Include optimized calls for OpenCV and OpenVX.

The OpenVino SDK is a toolkit launched by Intel specifically to simplify deep learning development. It can help developers deploy trained models to the target platform for inference. One of the benefits of OpenVINO is that it can write a program and then choose to run on various Intel hardware based on the workload. For example, the same deep learning model can run on Intel Xeon, Atom, Core and other processors.

OCR deep learning solution supports the input of control positioning. The faster the OCR recognition speed, the more it will help improve the speed of automation. The Intel OpenVINO tool suite optimizes OCR deep learning solutions to achieve multiple performance improvements in OCR recognition. Solutions such as data annotation and OCR recognition based on deep learning technology help customers complete automated application testing, which greatly reduces labor intensity.

ü Help various obvious or potential problems in automated, full-path exploration applications, extract feature training, and identify business functions

ü Visualize the execution process, making the positioning of the test link faster and more accurate.

ü For users, automated test management and test case creation can significantly reduce the waste of test time and resources and accelerate the time to market for applications.

OCR technology captures the image of the recognized character, performs specific algorithm processing on the image, and compares and matches the recognized character with the template library to achieve the purpose of character recognition. OCR is very useful in terms of product reproducibility.

Marking symbols, including identification of different fonts, languages, sizes, shapes, and colors, such as identifying whether the labels on beverage bottles are printed correctly.

ü Training: Collect image data and use existing image data to build models of target objects and their attributes in a high-performance server environment.

ü Reasoning: Deploy trained models in a factory environment to evaluate and identify such models in new images (such as identifying text or detecting defects).

ü Retraining: If production environments change, such as deviations in optics, lighting, or product specifications, the data distribution may change. The retraining process will collect new images and then update the model.

Deep learning helps new breakthroughs in traditional machine vision

OCR is primarily used to identify and read alphanumeric text on labels, materials, parts, and finished products, which is critical to ensuring product traceability throughout its life cycle. As for the challenges faced by the OCR system in identifying fonts, languages, text sizes, and colors, the deep learning-based OCR solution developed by Future Robot Technology provides a new method. It reduces the complexity of recognition through image tagging, training and inference processes, and makes up for the shortcomings in traditional OCR recognition. In addition, with the retraining process of continuously collecting new images, the OCR system will become more accurate, and the system's adaptability will be increased, so that the recognition will become more intelligent.

The application of deep learning solutions in product traceability, which can decode barcodes; can identify OCR or 2D codes on materials, parts, material boxes and finished products in real time in order to track product quality issues or make various timely decision making.

This machine vision solution incorporating deep learning technology not only can simplify processes, improve efficiency, and obtain more accurate inspection results in terms of OCR and defect detection; it is also used in the most common guidance and positioning applications on the production line. The system can also help users improve production efficiency, reduce costs, and enhance competitive advantage.

Solution

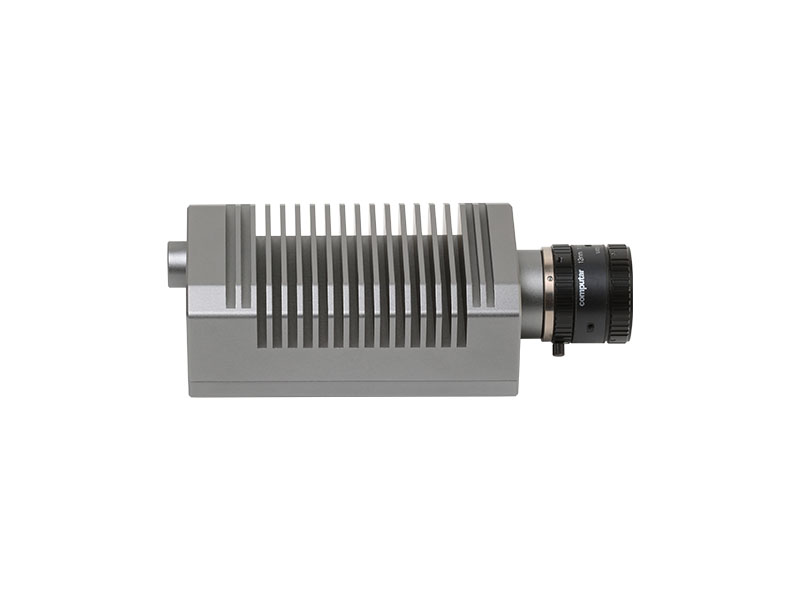

In realize of this, the RVS-2100 smart camera solution from Future Robot Technology Co. Limited provides all of the key components for a modern 120-fps machine vision solution in a compact, ruggedized package (Figure 1). And it’s available in an off-the-shelf development kit that allows innovating on top of baseline technologies.

Figure 1. The RVS-2100 smart camera. (Source: Future Robot Technology Co., Limited)

RVS-2100 smart camera solution features:

l New generation Intel Apollo Lake x86 platform

l 1.3-12MP CMOS sensor

l FPGA co-processor

l Easy deployment for its compact design

l No burden on cross-platform software & language, shorten product time to market

l Support OpenVino

In particular, the broad I/O support and interface flexibility enabled by the FPGA allow quick defining unique implementations for specific use cases. For example, communications and control can be established between the smart camera and human-machine interfaces (HMIs) or programmable logic controllers (PLCs). The Gigabit Ethernet interface can even be used to support an additional high-throughput slave camera for multi-angle installations.

Smart Camera RVS-2100 is powered by Intel CPU & LAN

Intel® Apollo Lake delivers high processing performance at low TDP for Industrial Smart Camera with high reliability and supporting ultra-compact size design, remote management and end-to-end security.

Bring powerful computer vision technology to new places with revolutionary Intel® Vision products. With the right performance, cost, and power efficiency at every node, you can scale vision technology across your infrastructure and unlock new possibilities for visual data. Intel Vision products including the Intel OpenVINO toolkit accelerate the capabilities of IoT vision systems and deep learning inference where you need it-from the camera to the cloud. This gives you insights at the right place and time, so you can make decisions faster and implement new operational strategies to drive immediate results

Future Robot’s Smart Camera RVS-2100 is an Intel® IoT RFP Ready Kit Solution. Intel® IoT RFP Ready Kits are focused technology offerings that solve a class of market problems, have been deployed and tested in the field, and provide bundled hardware, software, and support. The technology is scalable and designed to grow with customer requirements-enabling accelerated development and time to market. Intel is working with partners including Future Robot to develop and deliver these innovative RFP Ready Kit Solutions so that we can empower businesses to achieve real results, today.

The industrial smart camera assists smart warehouse, intelligent logistics and smart factory, supporting applications such as character recognition, defect detection, visual positioning, object measurement, and object sorting etc.

Future Robot Technology Co., Limited (Future Robot in short) is a high-tech innovation enterprise focusing on Intelligent Manufacturing and Artificial Intelligence. Future Robot, with strong R&D capability and market demand-orientation, design and provide worldwide enterprises and individual users with Industrial Smart Camera, Vision Controller, Fanless Embedded Computer, PoE Frame Grabber, USB3.1 Expansion Card products which are for Industrial Automation, Robot, Machine Vision, Medical Application, Intelligent Transportation, Education and Internet of Things applications.

Expert team with rich experiences in Machine Vision, Motion Control and Edge Computing:

Hardware engineering team

- x86, FPGA, DSP, Layout and testing Engineers

Software engineering team

- BIOS engineers, FPGA, DSP, Algorithm software engineers and system development engineers.

Industrial and structure design engineering team

- structure design, multi board and model design

As a member of Intel IoT Solutions Alliance and partner of Intel IoT RFP Ready Kits, Future Robot Technology Co., Limited aim to provide reliable, high efficient and cost-effective standard and customized solutions for the customers worldwide.

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us