E700 Series Motion and Vision Controllers Based on Intel Comet Lake S Platform Offer Excellent Configurations for Intelligent Manufacturing Applications

Background

With the increasing demand for intelligent manufacturing, manufacturing enterprises are also increasing their requirements for intelligent and digital devices in industrial sites, and are paying more and more attention to the interoperability, high integration, high reusability and other qualities that can reduce costs and increase efficiency when laying out industrial sites.

Smart manufacturing as a huge systemic project, Future Robot and its partners choose to start from simple to complex, from typical application scenarios, using Intel advanced technology to provide customers with quality equipment and solutions for smart manufacturing systems. This article introduces the typical application of vision and motion control integrated system in industrial sites through Future Robot’s E700 series high performance motion and vision controller, which is built with the combination of Intel Comet Lake S high performance processor and Intel Cyclone IV FPGA chip.

Relevant technologies

The E700 series high-performance motion and vision controllers use Intel's 10th generation Comet Lake S platform processors, covering Core i7-10700E, i5-10500E, i3-10100E, Pentium Gold G6400E, Celeron G5900E and other CPU models, with highly flexible performance configuration range, which can flexibly meet different scenarios of industrial applications. They use 5 x intel i211-AT and 1 x i219-LM NIC chips, which support TSN network and fit the demand of high-speed communication in industrial sites. Adopting one Intel Cyclone IV FPGA chip to control 16 high-speed DIOs, supporting 200KHz high-speed pulse output and counting, which can meet various complex motion control requirements.

Solution

Future Robot’s customers build industrial applications based on the Intel Comet Lake S platform processor's E700 series motion and vision controllers with high performance data processing capabilities.

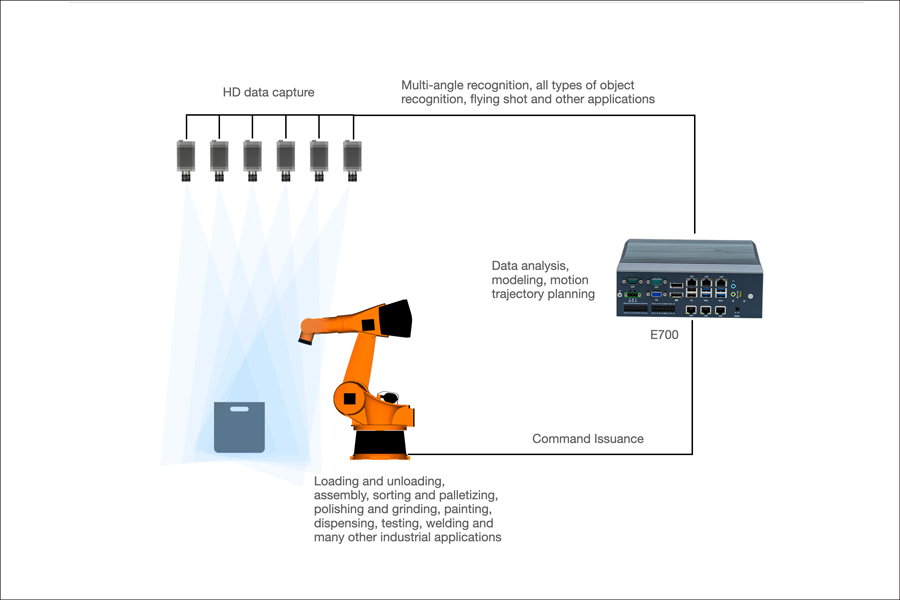

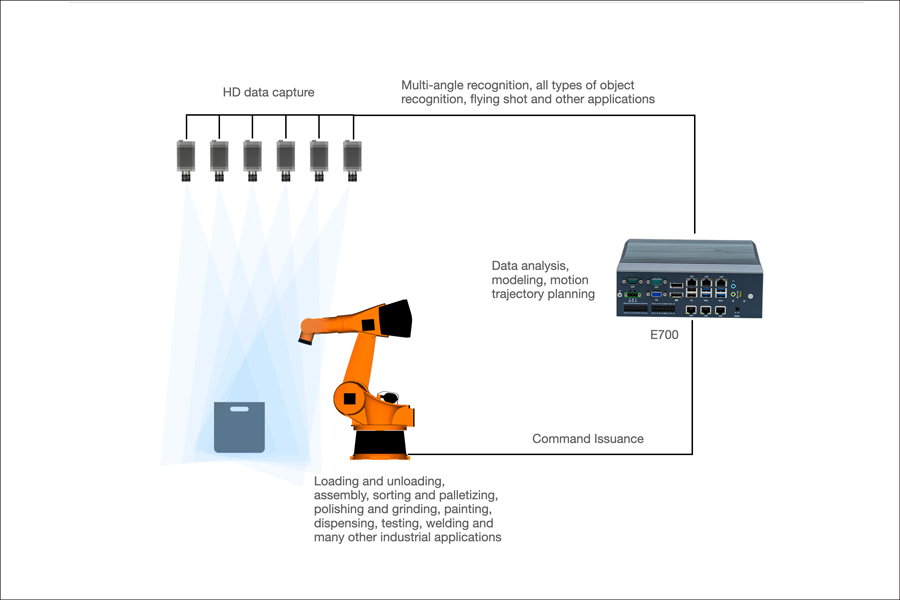

With 6 Gigabit high-speed network ports and 4 USB3.1 interfaces, the E700 series can connect up to 5 network interfaces and 4 USB3.1 interfaces to high-speed industrial cameras at the same time, in addition to 1 network port for data communication. By analyzing and processing the image data collected by the camera, generating commands, and then controlling the servo motor and robot arm through the DIO interface with high-speed pulse function controlled by Cyclone IV FPGA chip, it can realize complex industrial field applications such as high-speed flying shooting, alignment and lamination, object sorting, and flexible coating.

Solutions based on the E700 series motion and vision controllers have the following features and advantages.

Application scenarios cover a wide range and can be customized: E700 series motion and vision controllers use Intel Comet Lake S platform embedded CPU, covering different performance models from Celeron to Core level, which can flexibly adjust the performance configuration of the industrial controller according to the application requirements of industrial sites, and the rich IO interface is also very convenient for customizing various expansions to achieve convenient customization needs.

All-in-one, highly integrated and streamlined design: By directly connecting image and data acquisition devices such as industrial cameras and actuation devices such as motors and robotic arms controlled by high-speed DIO through the E700 series motion and vision controllers, the wiring of industrial sites and the complexity of connections between devices can be significantly streamlined, featuring high accuracy, speed and flexibility.

Convenient network access and convergence: E700 series motion and vision controller adopts Intel independent NIC chip-controlled network interface, supports TSN time-sensitive network, supports fast IT/OT network access, and meets the network performance requirements and application trends of industrial sites.

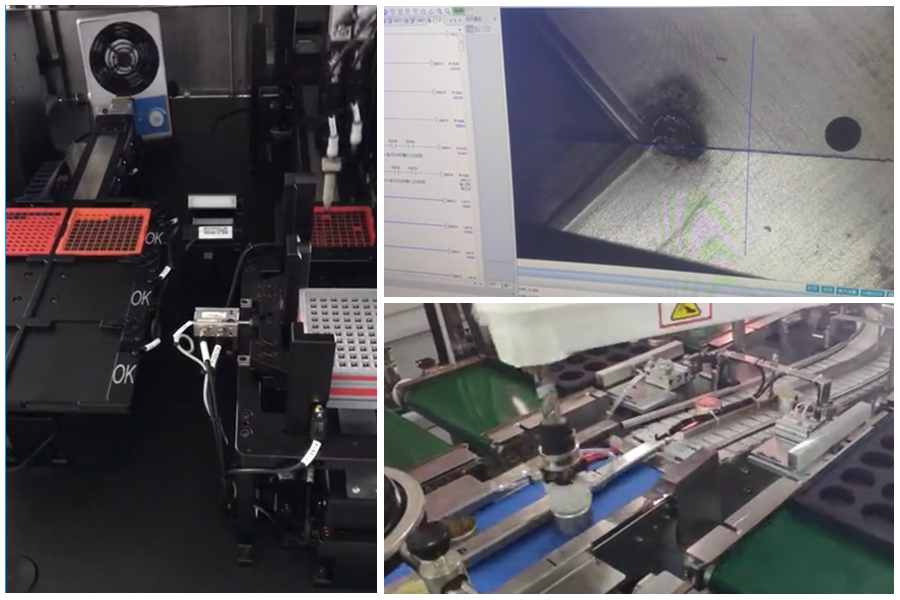

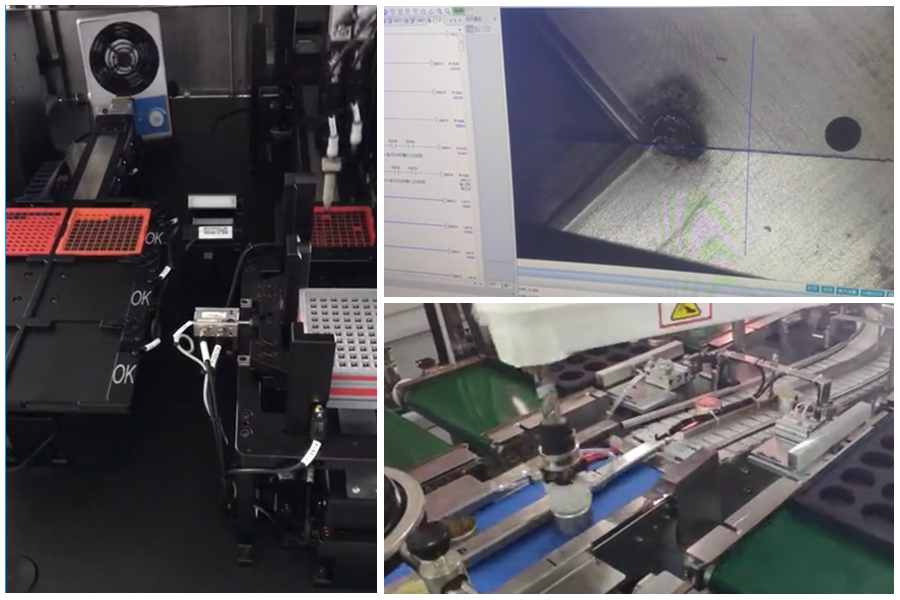

Currently, Future Robot's customers are using the E700 series high-performance motion and vision controllers with self-developed vision and motion control software to implement industrial applications in a variety of scenarios. For example: Sorting system using high speed flying camera and motion control for fast and high precision detection, identification and sorting picking; using the excellent computing performance of E700 series with motion planning technology allows users to deploy robot applications in a more simple and natural way, without manual teaching, and can automatically plan motion trajectories; using E700 series with 3D camera for point cloud acquisition and 3D modeling The E700 series is equipped with a 3D camera for point cloud acquisition and 3D modeling, enabling full coverage modeling of large objects and control of the slide rail and robot arm for operation. Use the E700 series to control the combination of robot arm and camera for inspection of welded joints, CNC machining effects, etc.

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us