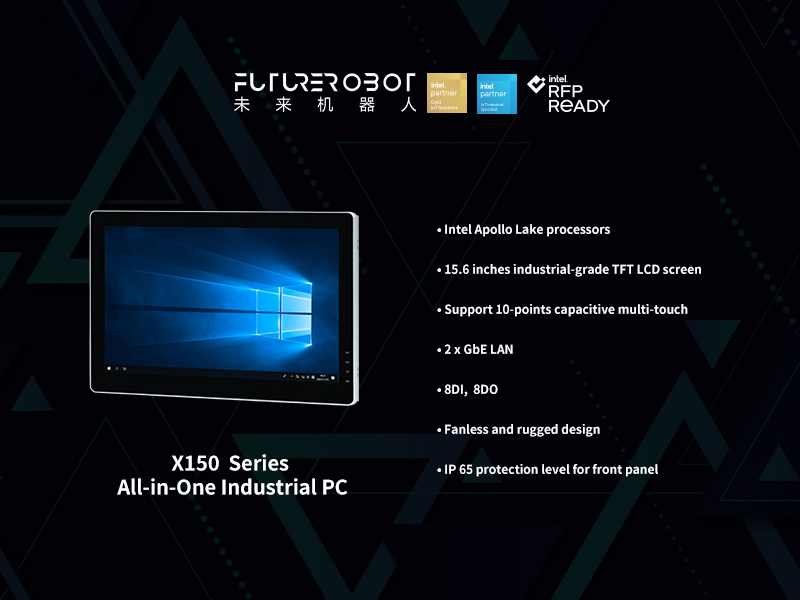

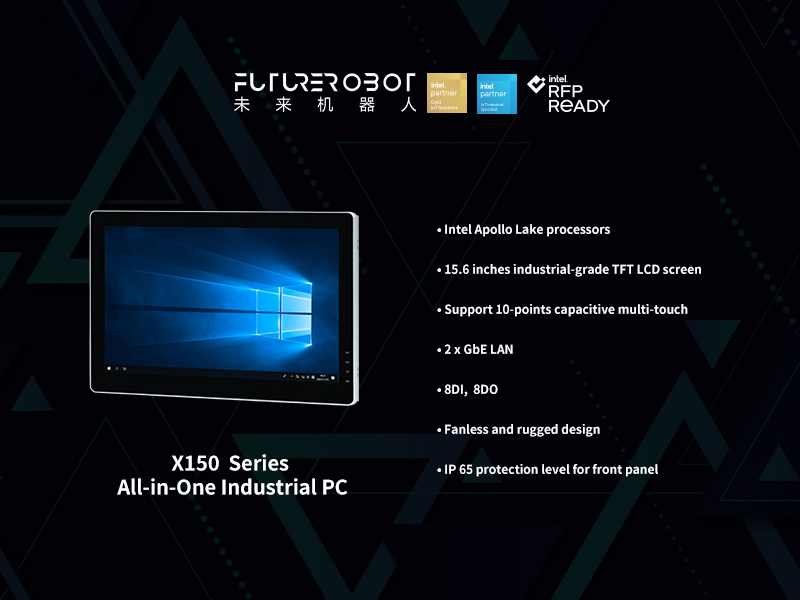

X150 Series All-in-One Industrial PCs Based on Intel Apollo Lake Platform Provide Better Solutions for Smart Manufacturing

Background

The continuous advancement of industrial automation, digitalization and intellectualization has brought more efficient production to many manufacturing enterprises and promoted the development and upgrading of many intelligent manufacturing equipment. The All-in-One IPC is growing in importance as a member of the industrial equipment product line and is becoming the control center of the production process and an indispensable field device.

Thanks to All-in-One IPC's screens that better reflect the status of equipment and processes, and bring more intuitive feelings to customers through visual and tactile effects, the demand and attention of All-in-One IPC is increasing in the automation industry in China. From manufacturing to food industry, logistics, etc., All-in-One IPC is flexibly applied to various systems, using touch panels to control and supervise manufacturing, production and shipping processes, supplemented by big data analysis to improve productivity and yield.

All-in-One IPC, as a category of IPC, has a complete performance of the whole machine and has the performance of the common industrial computers in the market. Therefore, the industrial site, the tablet PC with touch function will be the future trend, All-in-One IPC is also a kind of industrial control machine, and compared with the ordinary industrial control machine it has the following advantages.

All-in-One IPC front panel is made of die-cast aluminum-magnesium alloy to achieve IP65 protection level, which is strong and sturdy and durable.

The small size of All-in-One IPC makes it very easy to install and maintain.

Beautiful appearance and wide application.

All-in-One IPC adopts the structure of all-in-one machine, the main unit, LCD monitor and touch screen are combined into one, which has excellent stability.

Touch screen operation, more convenient and fast.

All-in-One IPC mostly adopts fanless design, using large finned aluminum blocks for heat dissipation, which consumes less power and is more silent, and excludes the stability problems brought by fan abnormalities and service life.

Technique

The X150 series All-in-One IPCs are powered by Intel Apollo Lake platform processors, available in J3355/J3455/J4205 models, and support up to 8GB LPDDR4 memory and 1TB+ SSDs with flexible performance configuration ranges to meet the application needs of different scenarios. The 2GbE LAN port is controlled by two intel i211-AT supporting TSN network, which fits the demand of high-speed communication in industrial field. The 8-way high-speed DIO controlled by one Intel Cyclone IV FPGA chip can meet the demand of motion control in industrial sites.

Solution

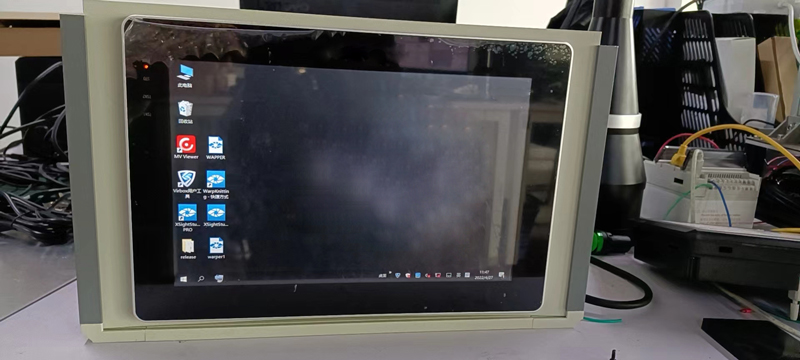

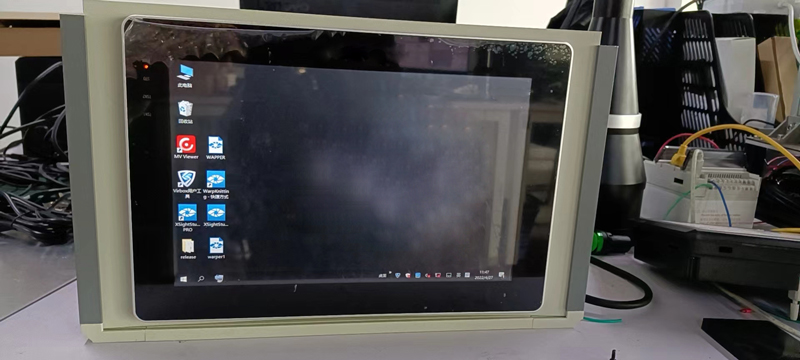

Future Robot's X150 series Fanless All-in-One IPC with Intel Apollo Lake SoC + FPGA platform, equipped with 15.6" industrial-grade 10-point capacitive screen touch screen, professional vision control function and high-performance image processing capability. The X150 series features professional vision control I/O interfaces, including two Intel Gigabit Ethernet ports, two USB 3.0 ports and two USB 2.0 ports, eight sets of isolated digital I/O, and two RS232 ports, one of which supports RS232/485/422, for real-time dynamic triggering and multi-camera simultaneous acquisition. X150 series All-in-One IPC, with compact design, feature-rich and multi-purpose, perfectly fits the trend of industrial field layout and greatly simplifies the complexity of field equipment, which can be widely used in industrial fields such as CNC machinery, 3C and CNC processing.

The X150 Series All-in-One IPC's solutions have the following features and benefits.

Excellent HMI functions and performance: Thanks to the advantages of the X150 series' excellent industrial-grade multi-touch screen, the X150 series can be easily accessed into the industrial site network and used as an excellent HMI device, while supporting FPGA-controlled high-speed digital input and output interfaces, which can easily expand digital IO devices.

Convenient network access and convergence: The X150 Series All-in-One IPC features a network interface controlled by the Intel i211AT standalone NIC chip, which supports TSN time-sensitive networks and jumbo frames for fast access to IT/OT networks.

Wide coverage of application scenarios: X150 series All-in-One IPCs use Intel Apollo Lake platform embedded CPUs, covering different performance models from Celeron to Pentium level, which can flexibly adjust the performance configuration of IPCs according to the application requirements of industrial sites, and the rich IO interfaces are also very convenient for customizing various expansions to achieve convenient customization requirements.

The X150 series All-in-One IPC based on Intel Apollo Lake platform has excellent interaction capability and performance configuration, and has been widely used in a variety of industrial scenarios, which can provide a more excellent configuration solution for intelligent manufacturing.

Future Robot Technology Co., Limited (Future Robot in short) is a high-tech innovation enterprise focusing on Intelligent Manufacturing and Artificial Intelligence. Future Robot, with strong R&D capability and market demand-orientation, design and provide worldwide enterprises and individual users with embedded products which are for Industrial Automation, Robot, Machine Vision, Medical Application, Intelligent Transportation, Education and Internet of Things applications.

Expert team with rich experiences in Machine Vision, Motion Control and Edge Computing:

Hardware engineering team

- x86, FPGA, DSP, Layout and testing Engineers

Software engineering team

- BIOS engineers, FPGA, DSP, Algorithm software engineers and system development engineers.

Industrial and structure design engineering team

- structure design, multi board and model design

As a member of Intel IoT Solutions Alliance and partner of Intel IoT RFP Ready Kits, Future Robot Technology Co., Limited aim to provide reliable, high efficient and customized solutions for the customers worldwide.

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing

ApplicationsProcessorsFeaturesApplicationsRugged Embedded Computing IOT Logistics Gateway

IOT Logistics Gateway ProcessorsFeatures

ProcessorsFeatures Sales and SupportSales and Support

Sales and SupportSales and Support ApplicationApplication

ApplicationApplication About usAbout us

About usAbout us